Introduction

In today’s fast-paced industrial world, progress without responsibility is no longer an option. India’s journey toward becoming a global manufacturing hub has created new environmental and compliance challenges — particularly in states like Gujarat, where heavy industries dominate the landscape.

From the chemical corridors of Dahej and Ankleshwar to the coastal plants of Hazira, industries face one key question:

“How do we grow without compromising environmental safety?”

Reconsky provides the answer through its FRP (Fiberglass Reinforced Plastic) engineering systems that combine compliance, durability, and sustainability — creating infrastructure that meets the toughest industrial and environmental standards.

“Compliance isn’t a checkbox for us; it’s built into our engineering DNA.”

— Reconsky Compliance Head

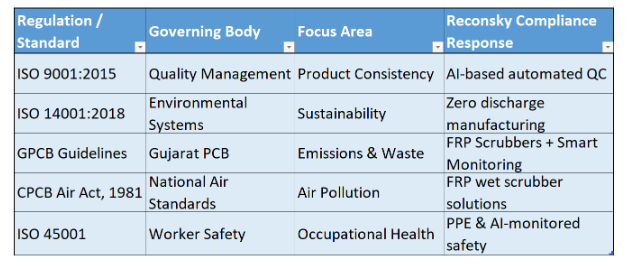

1. The Evolving Compliance Landscape in Indian Industry

As India industrializes rapidly, government bodies like GPCB, CPCB, and MoEFCC have tightened environmental and operational standards.

Traditional materials and legacy equipment often fail to keep up with these benchmarks — leading to leakage, emissions, and costly penalties.

Reconsky’s approach is different:

It designs and manufactures FRP-based systems — scrubbers, tanks, blowers, and lining solutions — that inherently meet compliance standards because of their material properties and smart integrations.

Explanation:

By designing around these standards, Reconsky ensures its customers stay audit-ready at all times — eliminating the usual rush for compliance paperwork before inspections.

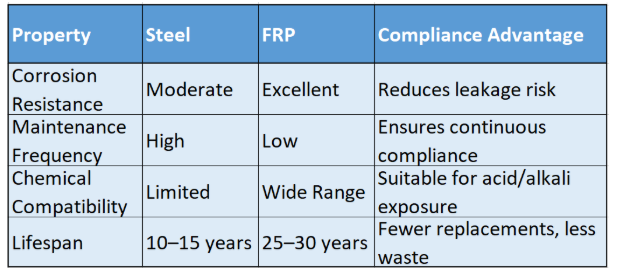

2. Why FRP is the Backbone of Sustainable Compliance

Steel and concrete have long been the backbone of Indian infrastructure — but they corrode, leak, and degrade under harsh chemicals.

FRP (Fiberglass Reinforced Plastic) is changing that narrative. Its corrosion-resistant and chemically inert properties make it ideal for Gujarat’s harsh industrial climates.

“FRP isn’t just a material upgrade — it’s a compliance solution built into the structure itself.”

— Reconsky Technical Head

Supporting Explanation:

A plant using FRP tanks instead of metal not only avoids corrosion-related spills but also stays compliant with ISO 14001 and GPCB waste management standards.

Every product Reconsky delivers — from FRP blowers to chemical scrubbers — helps clients move closer to sustainable industrialization.

3. How Reconsky Redefines Green Manufacturing

Reconsky’s Vadodara facility is more than a manufacturing plant — it’s a model for eco-conscious production.

It operates on a closed-loop sustainability model built around five core pillars.

🌞 1. Energy Efficiency

-

Automated curing systems adjust heat and humidity using AI sensors.

-

Reduces electricity consumption by 25% annually.

-

Solar-integrated power supports 30% of total operations.

💧 2. Zero Liquid Discharge (ZLD)

-

Wastewater from resin and lamination processes is filtered, treated, and reused.

-

Achieved ZLD certification in 2023.

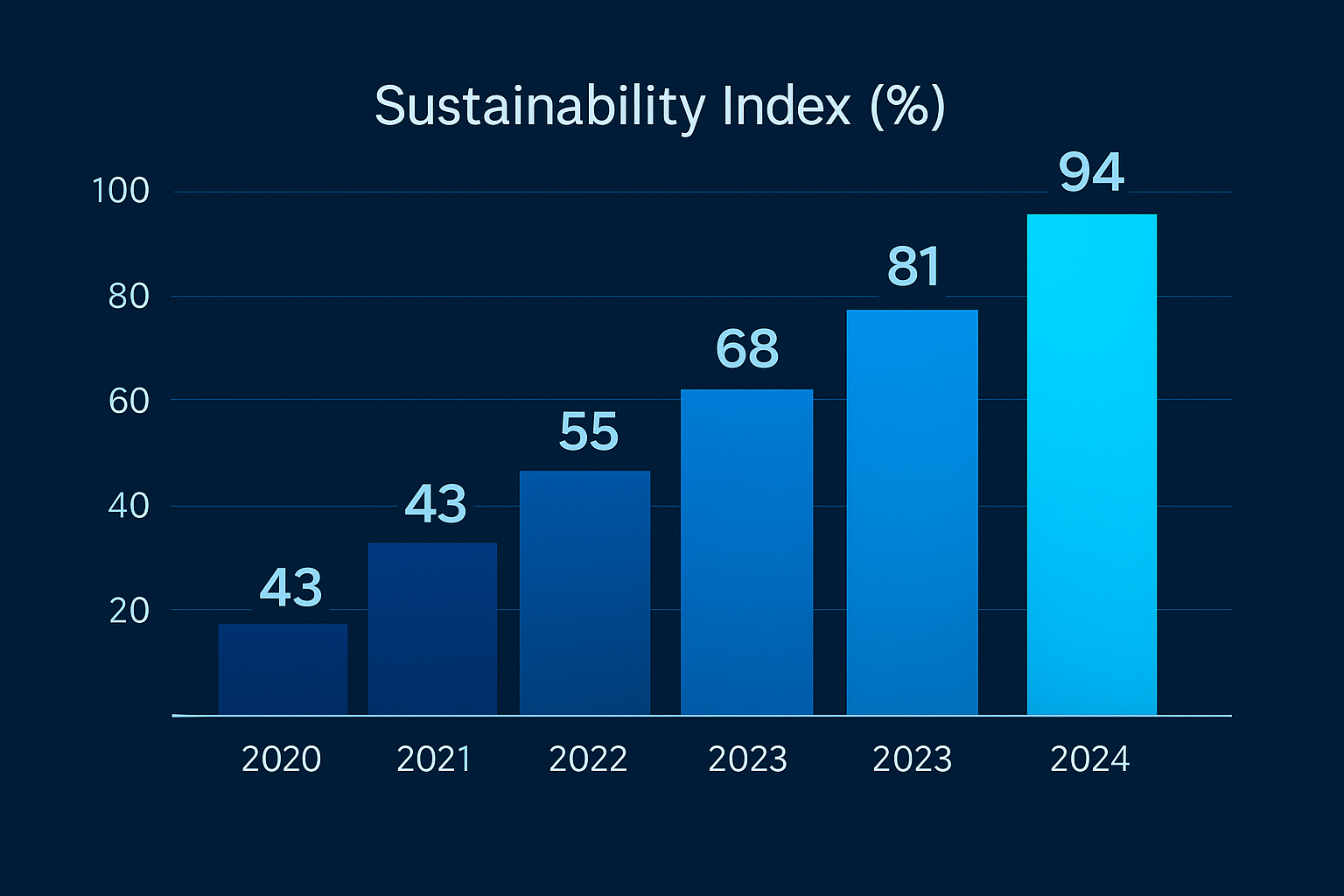

🔁 3. Waste Circularity

-

FRP scrap is recycled into low-load components (e.g., cable tray bases).

-

Waste reuse increased from 25% (2020) to 78% (2024).

🏭 4. Green Sourcing

-

Resins and glass fibers procured from GPCB-approved local vendors.

-

Cuts transport emissions by 12%.

🌱 5. Air Quality Monitoring

-

On-site scrubbers maintain <5 ppm emissions (GPCB benchmark = 10 ppm).

-

IoT-connected monitors ensure real-time compliance.

Graph 1: Reconsky’s Sustainability Growth (2020–2024)

Explanation:

Reconsky’s four-year sustainability journey shows how a manufacturing plant can evolve from basic efficiency to holistic environmental responsibility — without sacrificing productivity.

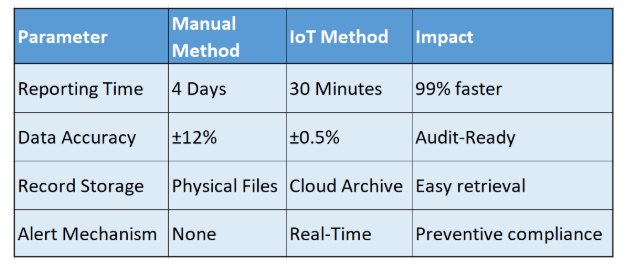

4. Digital Compliance: From Manual Logs to Smart Data

Industrial compliance once meant paperwork, checklists, and delayed responses.

Reconsky digitized this process by integrating IoT sensors and automated compliance dashboards into its equipment.

Supporting Example:

At a chemical plant in Ankleshwar, IoT-linked FRP scrubbers alert operators when air emission levels exceed thresholds — enabling preventive action before a GPCB alert. That’s compliance in real-time, not reaction-time.

“Digital compliance is no longer an add-on — it’s the future of responsible engineering.”

— Reconsky Automation Lead

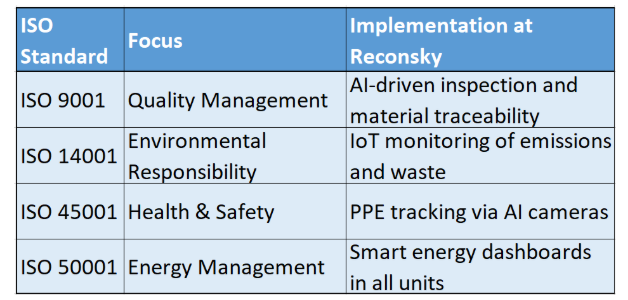

5. ISO Standards as a Culture, Not a Certificate

Many manufacturers treat ISO certification as a one-time milestone. Reconsky embeds it into every process — from design to dispatch.

Insight:

This continuous audit-readiness ensures Reconsky’s systems are not only compliant but ahead of upcoming global benchmarks like EU REACH and ESG disclosure frameworks.

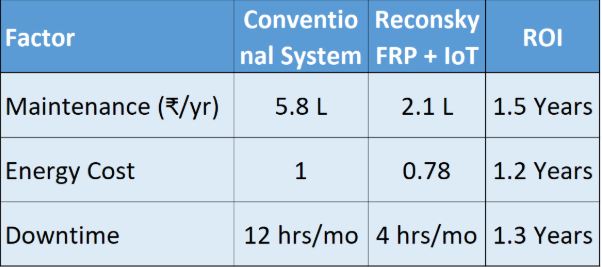

6. Sustainability ROI — The Business Logic Behind Green Engineering

Sustainability is not just ethical — it’s economically smart.

Reconsky’s clients report faster ROI and lower operational risks after adopting FRP-based and automated systems.

Explanation:

The savings achieved through predictive maintenance and zero-leakage operations far outweigh initial investment costs.

Within 18 months, clients typically recover their costs and start compounding long-term environmental and financial gains.

7. The Road Ahead — Toward Circular Composites

Reconsky’s future sustainability roadmap focuses on circular manufacturing — creating products designed to be reused, repurposed, and recycled.

Upcoming Initiatives (2025–2027):

-

Bio-Resins: Derived from agricultural waste to replace petroleum-based resins.

-

Recyclable FRP: Using thermoplastic composite hybrids.

-

Blockchain Traceability: Full transparency from raw material to delivery.

-

Smart Solar FRP Covers: Energy-producing infrastructure components.

“Circular composites will define India’s industrial future — materials that don’t just serve but sustain.”

— Reconsky Innovation Director

8. Case Study: Sustainable Transformation in Dahej

A large fertilizer company in Dahej replaced metal tanks and blowers with Reconsky’s FRP-based systems.

Challenges Before:

Frequent corrosion, emission leaks, and high downtime.

Reconsky Intervention:

Installed FRP dual-laminate tanks, IoT scrubbers, and motor guards.

Outcome (12 months):

-

35% energy reduction

-

95% emission control efficiency

-

GPCB compliance maintained continuously

This case proves that sustainability and profitability can coexist when innovation leads the way.

9. Key Takeaways

-

Compliance begins with design — not documentation.

-

FRP materials provide an in-built environmental advantage.

-

IoT transforms compliance from reactive to proactive.

-

ISO standards form the backbone of modern accountability.

-

Reconsky’s Gujarat-based innovations are shaping India’s global reputation for responsible manufacturing.

Conclusion

Reconsky stands as a symbol of India’s new industrial ethos — one where growth, responsibility, and technology go hand in hand.

By merging FRP innovation, smart automation, and sustainable design, it’s redefining how Indian industries meet global expectations while protecting local ecosystems.

“We don’t just make compliant products — we build a compliant future.”

— Reconsky Founder & CEO