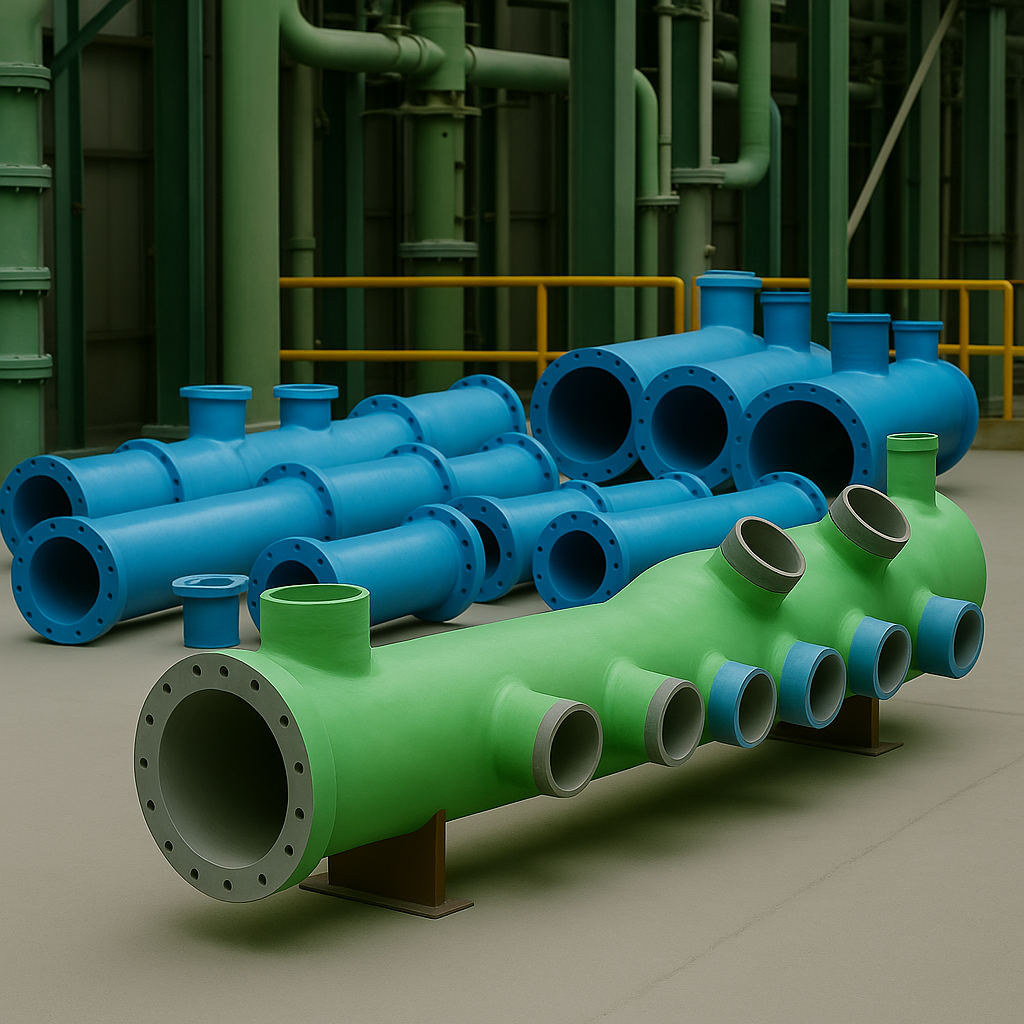

Engineered Solutions for Demanding Industrial Applications

At Reconsky Fiber Glass Pvt. Ltd., we specialize in the manufacture and supply of high-performance FRP (Fiber Reinforced Plastic) Headers—engineered to deliver unparalleled durability, chemical resistance, and structural integrity across a vast spectrum of industries. Leveraging advanced manufacturing technology and premium raw materials, Reconsky FRP headers are the trusted choice for critical process pipelines and header systems worldwide.

Why Choose Reconsky FRP Headers?

Reconsky FRP Headers are crafted using superior fiberglass-reinforced polyester resins, delivering exceptional mechanical strength while remaining remarkably lightweight and easy to handle. Our expertise ensures every header system is fabricated to the highest quality standards and rigorously inspected for reliable, leak-proof operation—making them ideal for harsh and corrosive environments.

Key Benefits

Corrosion and Chemical Resistance

Withstand aggressive chemicals, acids, and saline conditions, ensuring extended service life even in the toughest plant environments.

Superior Strength-to-Weight Ratio

Robust structural properties combined with ease of handling and installation.

Long-Term Durability

Designed for a lifespan of up to 50 years with minimal maintenance.

Leak-Proof and UV Stabilized

Engineered to maintain structural and hydraulic integrity under demanding operational conditions, indoors or outdoors.

Low Maintenance & Cost Effective

Reduce downtime, eliminate the need for linings, cathodic protection, or coatings, and offer substantial lifecycle savings.

FRP Header Types We Offer

Reconsky provides a complete portfolio of FRP headers for diverse process and utility systems:

- Open Channel Header

- Closed Channel Header

- Manifold Header

- Radial Flow Header

- Parallel Flow Header

- Cross-Flow Header

- Header & Lateral System

- Grid Header

- Single/Multiple Entry/Exit Configurations

- Special Application

- Anolyte / Catholyte FRP Headers for Chlor-Alkali, Electroplating, and Electrochemical Industries

Salient Features

- Light weight—easy to transport and install

- Lifespan up to 50 years

- High-pressure and buckling resistance

- Hydraulic efficiency thanks to superior smooth internal finish

- UV stabilization and temperature insulation

- Designed for fast project execution and flexible on-site modifications

- Compliance with global engineering standards (AWWA, BS, ASTM, ISO, DIN, API)

Technical Specifications

- Design Standards: AWWA M45, BS 6464, BS 7159, ASTM D3982, ISO 14692, API 15LR, ASME B31.3, DIN 16965 & 16966, AS 2634

- Diameter Range: From 25 mm up to 4000 mm (design dependent)

- Pressure Range: 1 Bar to 32 Bar (ISO), up to 450 psig (AWWA), or as per project requirements

- Stiffness Class: 62 to 10,000 N/m² or as per international and BIS codes

- Length: 3.0 to 12.0 meters or custom lengths on request

- Materials of Construction: Polyester, Isophthalic, Bisphenol, Vinyl Ester, Superior Grade Vinyl Ester, Epoxy Resins with premium fiberglass reinforcements

- Quality Certifications: As per IS 12709, IS 14402 (BIS), AWWA C950, ISO 10639, ISO 10467, ASTM D2996, API 15LR, DIN 16965/16966 standards

Common Applications:

- Chlor-Alkali Plants and Electroplating Facilities

- Chemical and Petrochemical Production

- Process Manifold and Distribution Systems

- Sewage and Water Treatment

- Desalination and Redox Flow Batteries

- Electrochemical Cells and Research Applications

- Construction, Marine, Aerospace, and Automotive Industries

Why Reconsky?

With years of industry experience, a rigorously trained team, and cutting-edge facilities, Reconsky delivers solutions designed for productivity, safety, and total reliability. Every product is backed by our technical expertise and customer-first philosophy.

Frequently asked questions

FRP headers are main distribution or collection manifolds fabricated from fiberglass reinforced plastic, designed to distribute or collect fluids or slurries across multiple laterals, branches, or process lines. They are widely used in chlor-alkali plants, electroplating lines, chemical process manifolds, desalination plants, sewage and water treatment plants, and advanced filtration systems where corrosion resistance and long life are critical. Typical configurations include open-channel headers, closed headers, manifold headers, radial-flow and parallel-flow headers, and grid-type header and lateral systems. In water and wastewater treatment in Gujarat’s industrial clusters, FRP headers are commonly installed in filtration, equalisation, and distribution systems because they can withstand aggressive media and high flows with minimal maintenance. Their lightweight and modular nature also helps EPC contractors and OEMs simplify design, installation, and future expansion.

Reconsky FRP headers offer exceptional resistance to corrosion, erosion, and chemical attack, even under continuous exposure to aggressive chemicals, saline water, and industrial effluents. Unlike MS headers, they do not require internal rubber lining, frequent repainting, or cathodic protection, which significantly reduces maintenance interventions and downtime. Compared to PVC or other basic thermoplastics, FRP headers provide far superior mechanical strength, temperature resistance, and pressure-handling capacity, making them suitable for higher design pressures and large diameters. With properly engineered design and resins, FRP headers can deliver service lives of up to 50 years, which makes their lifecycle cost much lower than conventional materials despite slightly higher initial capex. For clients focused on long-term reliability and reduced total cost of ownership—especially in critical process lines—FRP headers are a very compelling upgrade.

Reconsky designs FRP headers as per recognised global standards such as AWWA M45, BS 6464, BS 7159, ASTM D3982, ISO 14692, API 15LR, DIN 16965/16966, and related codes for GRP / FRP piping systems. Diameter ranges typically start around 25 mm and can go up to 4000 mm depending on application and design constraints, covering everything from small process manifolds to large header–lateral systems in STPs and WTPs. Pressure ratings are engineered from roughly 1 bar up to 32 bar (or up to around 450 psig) depending on standard, resin system, laminate design, and safety factors specified by project requirements. Stiffness classes from 62 to 10,000 N/m² can be provided to meet international and BIS codes, ensuring adequate resistance to external loads, burial, and handling stresses. Standard lengths of 3 to 12 metres can be supplied, with customised spools and complex geometries developed to suit site layout and nozzle arrangements.

For each project, Reconsky evaluates fluid characteristics (chemical composition, temperature, pH, solids), operating pressure, temperature, and installation environment to select the appropriate resin system and laminate structure. Available resin options include polyester, isophthalic, bisphenol, vinyl ester, superior-grade vinyl ester, and epoxy, allowing precise tuning of chemical and temperature resistance. For special applications such as anolyte and catholyte headers in chlor-alkali, electroplating, and electrochemical cells, specialised FRP header designs and materials are used to withstand highly oxidising conditions. Configurations such as manifold, radial flow, cross-flow, header-and-lateral grids, and single or multiple entry/exit designs are tailored to hydraulic requirements and equal flow distribution. This high degree of customisation ensures that system performance, reliability, and safety requirements are consistently met for demanding end users and OEMs in Gujarat and across India.

For EPCs and OEMs, Reconsky FRP headers provide a reliable, standards-compliant solution that simplifies design and reduces risk on large projects involving corrosive or demanding service conditions. Their light weight and ease of handling reduce lifting requirements and speed up erection, especially in tight or elevated spaces such as clarifiers, filter galleries, or process racks. Plant owners benefit from leak-proof, UV-stabilised, and mechanically robust header systems that require minimal maintenance, do not corrode, and maintain hydraulic performance over decades. Because they are fabricated to international and BIS standards and backed by test certificates, FRP headers also help clients satisfy consultants, auditors, and global customer requirements for quality and reliability. This combination of technical performance, reduced downtime, and strong documentation support makes Reconsky FRP headers an excellent long-term investment for water, wastewater, and process industries.