Advanced Corrosion Protection for Industrial Assets

Reconsky Fiber Glass Pvt. Ltd. offers industry-leading FRP (Fiberglass Reinforced Plastic) lining solutions, providing unmatched resistance to corrosion, chemicals, abrasion, and leakage. Our high-performance FRP linings are engineered to protect a wide range of surfaces and equipment, dramatically extending service life and reducing maintenance costs for clients in challenging industrial environments.

Key Features

Exceptional Chemical Resistance

Shields against acids, alkalis, solvents, salts, and aggressive industrial chemicals—even at elevated temperatures .

100% Leak Proof & Impermeable

Prevents seepage and structural damage, protecting tanks, floors, drains, pipes, reactors, and more.

High Strength-to-Weight Ratio

Offers excellent structural reinforcement without adding significant weight.

Hygienic & Food-Grade Options

Smooth, non-toxic, and easy-to-clean surfaces for food, pharmaceutical, and water applications.

UV and Weather Resistant

Proven durability even in outdoor and aggressive environments.

Low Maintenance & Long Life

Service life of 10–20+ years with minimal upkeep.

Customizable Thickness & Color

Tailored to client’s needs, with a variety of finishes and thicknesses up to 10–20mm or more per requirement.

Applications

- Tanks (MS, RCC, PP, PVC): Pickling, plating, chemical process, storage tanks (internal and external).

- Pipelines: Water supply, drainage, effluent treatment, chemical transfer lines.

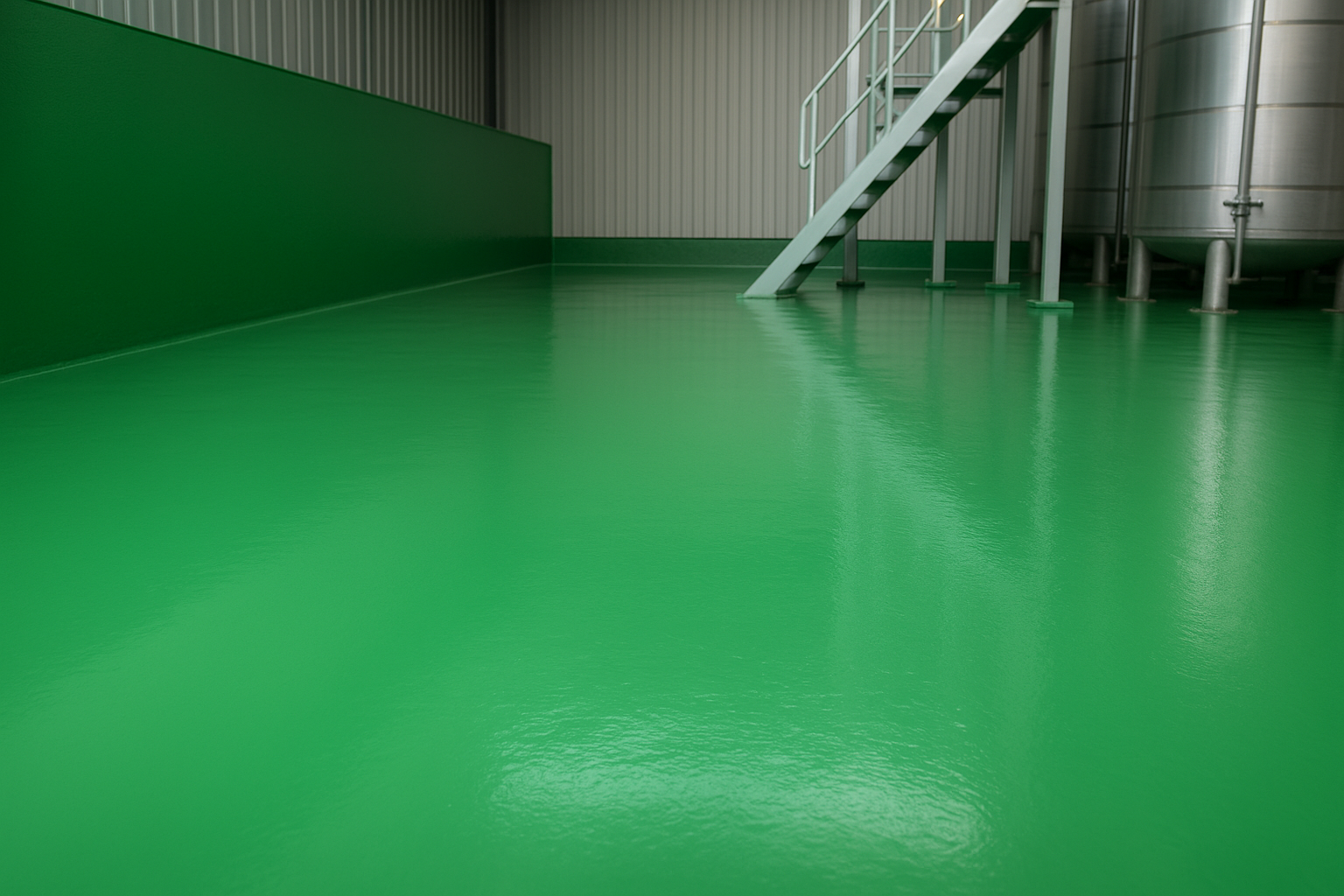

- Floors & Pits: Chemical spillage zones, neutralizing pits, washing/safety areas, laboratories, battery rooms, cell houses.

- Scrubber Systems & Chimneys: Internal lining for scrubbers, ducts, exhaust stacks.

- Metal Finishing Plants: Electroplating, galvanizing, anodizing tanks and sumps.

- Construction: Waterproofing and protection of concrete basements, terraces, and rooftops.

- Others: Marine, pulp and paper, fertilizer, petrochemical, mining, and infrastructure sectors

Why Choose Reconsky’s FRP Lining?

- Advanced Manufacturing:Latest hand layup, spray-up, and extruded molding processes ensure uniform, high-strength linings.

- Versatility: Suitable for on-site application on flat, curved, vertical, or complex geometries.

- Global-Standard Materials: Only certified, world-class resins and reinforcement used.

- Comprehensive Quality Checks: Rigorous testing and inspection before handover.

- Expertise: Team with decades of experience and rapid project turnaround.

Technical Customization

- Layer Build-Up & Thickness:From standard 3mm up to 20mm+

- Surface Preparation: Grit blasting, chemical cleaning, priming as required

- Accessories: Integration with inlet/outlet nozzles, manholes, vents, and more

- Documentation: Test certificates and method statements provided

Contact Reconsky Fiber Glass Pvt. Ltd. to Protect Your Assets

Reconsky – Your trusted partner for reliable, long-lasting industrial FRP lining and

corrosion protection. Enhance durability. Prevent leaks. Invest in Reconsky’s advanced

FRP lining solutions today.

Frequently asked questions

FRP lining is a reinforced composite barrier made from fiberglass and high-performance resins (Isophthalic, Vinyl Ester, Super Vinyl Ester, Epoxy) applied over substrates like RCC, MS, PP, PVC, or brick to protect against corrosion, leakage, and abrasion. Compared to rubber or epoxy coatings, FRP linings offer far better chemical resistance across a wide pH and temperature range, along with much higher mechanical strength and impact resistance. Unlike tiles or bricks, FRP creates a seamless, joint-free surface, eliminating grout joints that often crack and become leak paths in chemical plants. For heavy-duty applications in pickling tanks, ETP sumps, chemical floors, or scrubber bodies—especially in high-corrosion belts like Ankleshwar or Vapi—FRP lining provides longer life and lower maintenance than most alternatives. It is particularly attractive for clients who want to extend the life of existing RCC or MS structures without full replacement, while still meeting safety and compliance expectations.

Reconsky FRP lining is widely used in chemical, pharmaceutical, fertilizer, metal finishing, pulp & paper, mining, and wastewater treatment industries where exposure to aggressive acids, alkalis, and solvents is routine. Typical assets lined include internal surfaces of MS or RCC tanks, process vessels, neutralisation pits, drainage channels, scrubbers, chimneys, battery rooms, and spill containment areas. In ETP and STP facilities, FRP lining protects concrete tanks, collection pits, and aeration basins from long-term chemical attack and seepage into soil or groundwater. For food and pharma plants, hygienic FRP linings with smooth, easy-to-clean surfaces and food-grade resin systems help maintain cleanliness and avoid contamination. Construction segments also use FRP lining for waterproofing basements, terraces, rooftops, and structures that must resist moisture plus chemical exposure.

Reconsky customises FRP lining systems using resin types such as Isophthalic polyester, Vinyl Ester, Super Vinyl Ester, and Epoxy, chosen based on chemical compatibility and operating temperature. Typical lining thickness starts from around 3 mm for moderate-duty applications and can go up to 10–20 mm or more for highly corrosive or mechanically stressed areas. Standard systems handle temperatures up to about 100 °C, while specialised resin formulations can be selected for higher-temperature services as required. Build-up is usually done in multiple layers (chopped strand mat, woven roving, surface veil) to balance chemical resistance, mechanical strength, and flexibility. Colour and finish can be customised to improve visibility, cleaning, and area identification (for example, different colours for acid pits, alkali pits, or neutral areas in a Gujarat ETP plant).

Before FRP lining, Reconsky teams prepare the substrate by grit blasting, wire brushing, or chemical cleaning to remove loose particles, rust, oil, and laitance, ensuring strong adhesion. A primer or tie coat compatible with both substrate and FRP system is applied, followed by carefully layered resin and fiberglass reinforcement using hand lay-up, spray-up, or other proven methods. Critical areas like corners, joints, nozzles, and manholes receive additional reinforcement to prevent stress cracking and leakage in service. After curing, the lining is inspected visually and by spark testing or other non-destructive methods, and where necessary hydrotested, to confirm that there are no pinholes, holidays, or weak spots. Detailed documentation, including material batch certificates and test reports, is provided so customers can show compliance during internal safety audits or third-party inspections.

By acting as a robust, impermeable barrier, FRP lining protects concrete and steel structures from chemical attack, thereby preventing structural degradation, leakage, and costly unplanned shutdowns. A properly designed and executed FRP lining system can extend asset life by 10–20+ years with minimal maintenance, which significantly lowers lifecycle cost versus frequent rebuilding or re-lining. It also helps plants comply with environmental norms by preventing seepage of hazardous liquids into soil and groundwater, reducing risk of regulatory penalties and community complaints. For high-risk zones such as acid pickling tanks, battery rooms, and ETPs common in Gujarat’s industrial estates, FRP lining improves workplace safety and reliability, which is valued by insurers, auditors, and global customers. When combined with Reconsky’s experienced project execution and after-sales support, this makes FRP lining a strategic investment in plant reliability, compliance, and ESG positioning.