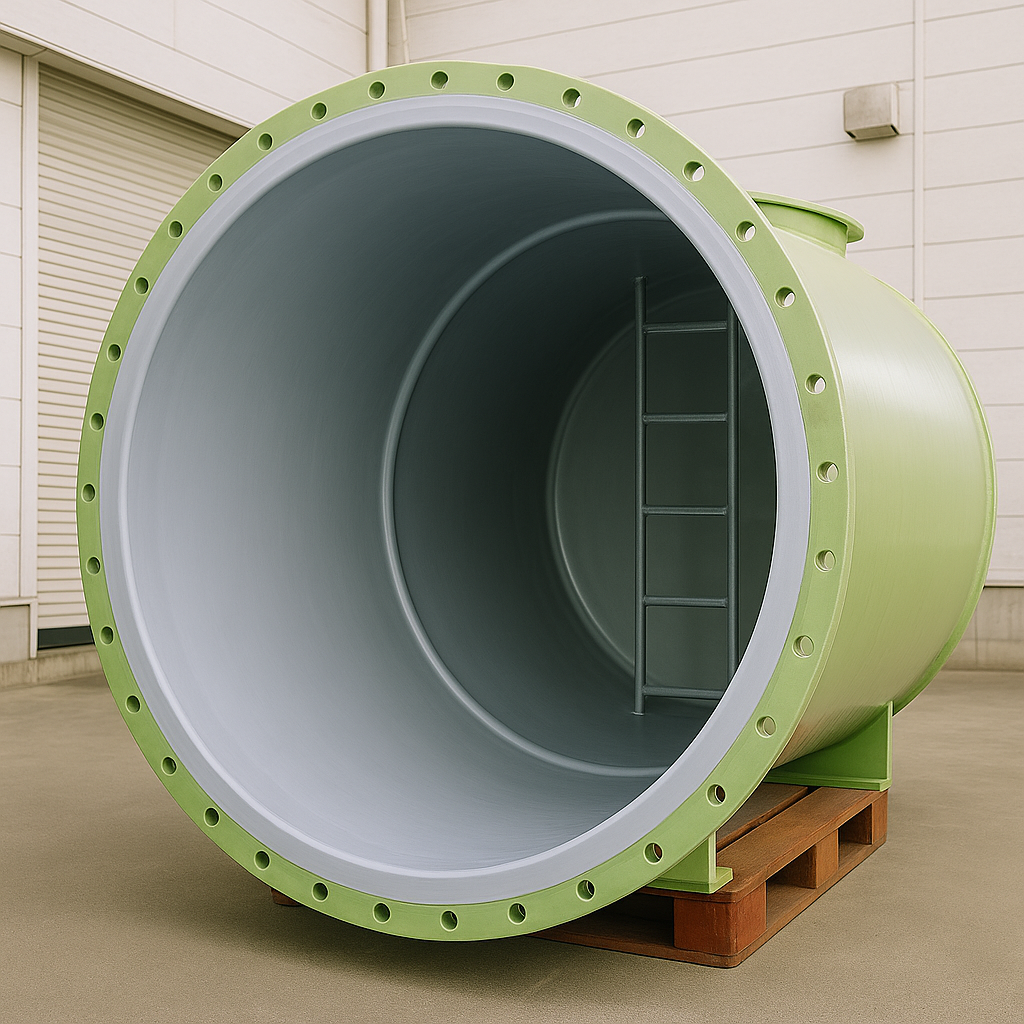

High-Performance Polypropylene Piping Solutions for Industrial and Process Applications

Reconsky Fiber Glass Pvt. Ltd. provides advanced Polypropylene (PP) Pipe systems engineered for outstanding chemical resistance, mechanical durability, and operational reliability in diverse industrial environments. Manufactured using premium thermoplastic grade PP and state-of-the-art extrusion technology, our PP pipes deliver corrosion-proof service, lightweight handling, and long-term cost efficiency.

What Are PP Pipes?

PP pipes are rigid, single-wall or dual-layer thermoplastic pipes fabricated from high-purity polypropylene. Unlike metallic pipes, PP pipes offer excellent resistance to a wide range of acids, alkalis, organic solvents, and effluents, making them ideal for transporting corrosive fluids, process chemicals, and wastewater.

These systems are lightweight yet robust, suitable for both above-ground and underground installations. Their smooth internal surface minimizes scaling, while their non-toxic composition makes them safe for potable water, food, and pharmaceutical applications.

Features and Benefits

Superior Chemical Resistance

Withstands aggressive chemicals including sulfuric acid, nitric acid, caustics, and solvents without corrosion or degradation.

Lightweight Construction

Easy to transport, handle, and install, reducing labor and structural costs.

Thermal Stability

Maintains mechanical integrity across a temperature range of -20°C to +100°C.

Non-Toxic & Food-Grade

Safe for food, beverage, and pharmaceutical use with smooth interiors that prevent microbial growth.

Low Friction Loss

Smooth bore ensures optimized flow rates and improved energy efficiency.

Flexible Jointing Options

Butt fusion, socket fusion, and mechanical fittings suit a wide range of project requirements.

UV & Weather Resistant

Suitable for prolonged outdoor exposure with resistance to sunlight degradation.

Long Service Life & Low Maintenance

Resists scaling, fouling, and mineral deposits, reducing ongoing maintenance costs.

Typical Applications

- Chemical processing plants transporting acids, bases, and process chemicals

- Potable water, cooling water, and effluent pipeline systems

- Pharmaceutical and food processing plants for hygienic fluid transfer

- Battery rooms and pickling lines in electrochemical environments

- Industrial HVAC vent piping, condensate drainage, and neutralization systems

- Agricultural and irrigation pipelines resistant to fertilizers and soil chemicals

Quality Assurance & Compliance

Reconsky manufactures PP pipes in accordance with ASTM, DIN, ISO, and IS standards for dimensional accuracy, strength, and long-term reliability. Each production batch undergoes rigorous testing for pressure tolerance, impact resistance, surface smoothness, and chemical inertness. Material certificates are provided for food and pharmaceutical applications.

Why Choose Reconsky PP Pipe Systems?

With over a decade of expertise in thermoplastic piping solutions, Reconsky offers customized diameters, wall thicknesses, pressure classes, and jointing methods. Backed by responsive technical support, competitive pricing, and fast delivery, our PP pipe systems deliver maximum return on investment for critical industrial infrastructure.

Frequently asked questions

A PP pipe system is a thermoplastic piping network made from high-purity polypropylene, designed to safely convey corrosive fluids, effluents, and process media in industrial and utility applications. Compared to MS or GI pipes, PP pipes are completely corrosion-resistant to a wide range of acids, alkalis, and salts, eliminating rust, scaling, and frequent repainting or lining. Versus PVC, PP offers better temperature resistance, improved impact strength, and superior chemical compatibility with many industrial reagents. Lightweight yet robust, PP piping is easier to install and support, reducing labour and structural steel requirements. For chemical, ETP, and process plants in Gujarat, PP piping provides long-term reliability with minimal maintenance and reduced risk of leakage or contamination.

Reconsky manufactures PP pipes in a wide range of diameters suitable for process lines, utility lines, and effluent transfer, in accordance with recognised standards such as ASTM, DIN, ISO, and IS. Pressure ratings are engineered to suit application requirements, with appropriate wall thickness and safety factors for low- and medium-pressure services. Jointing options include butt fusion, socket fusion, and mechanical fittings, allowing flexibility based on pipe size and site conditions. Smooth internal surfaces reduce friction losses, improving hydraulic efficiency and often enabling lower pumping energy. This makes Reconsky PP piping easy to integrate into both new and brownfield installations.

PP pipes are suitable for conveying a wide range of industrial fluids, including mineral acids, caustic solutions, many organic chemicals, and saline or brackish water, subject to chemical compatibility checks. They perform reliably over a typical temperature range of -20 °C to +100 °C, covering most ambient and moderately hot process conditions. In water and effluent services, PP pipes resist scaling and fouling far better than metal piping, maintaining consistent flow performance over time. Their non-toxic, non-leaching properties also make them suitable for certain food, beverage, and pharmaceutical utility applications where approvals apply. In battery rooms, pickling lines, and chemical transfer systems common in Gujarat’s industrial zones, PP piping offers a dependable alternative to metal pipes.

Reconsky manufactures PP pipes using high-grade raw materials and modern extrusion technology to ensure dimensional accuracy and consistent mechanical properties. Pipes are tested for pressure performance, impact strength, surface finish, and chemical resistance to confirm compliance with ASTM, DIN, ISO, and Indian standards. Material and test certificates are available for regulated projects such as pharma, food, and export-oriented installations. Reconsky also supports clients with engineering assistance for pipe sizing, support spacing, and layout design to manage thermal expansion and operating loads, ensuring long-term safe operation.

Reconsky PP piping offers strong commercial and operational advantages by eliminating corrosion-related failures, repainting, and internal lining repairs common with MS and GI systems. Its lightweight nature reduces transportation and installation costs, particularly on elevated pipe racks and congested industrial layouts. Smooth internal bores lower pumping energy requirements and minimise scale build-up, improving overall system efficiency. Easy jointing, long service life, and low maintenance requirements result in reduced downtime and predictable operating costs. For projects across Gujarat and India, Reconsky PP piping is a reliable, cost-effective solution for modern industrial fluid handling systems.