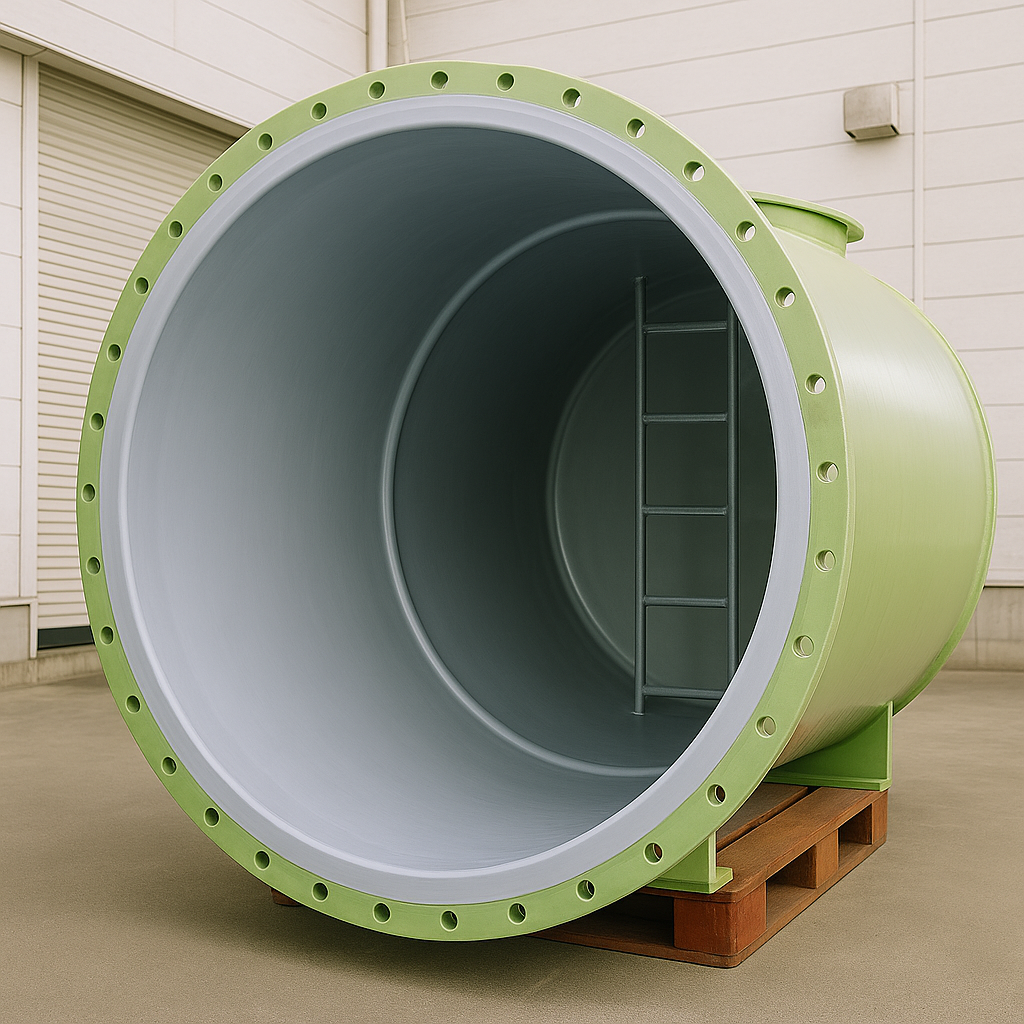

Comprehensive Polypropylene Lining Solutions for Industrial Protection

Reconsky Fiber Glass Pvt. Ltd. offers industry-leading Polypropylene (PP) Lining solutions designed to protect tanks, vessels, piping, floors, and reactors from severe chemical corrosion and physical wear. Utilizing premium-grade virgin polypropylene sheets and advanced thermal welding techniques, our linings deliver seamless, durable, and contamination-free barriers—critical for safe and reliable containment in harsh industrial environments.

What is PP Lining?

PP Lining is a corrosion-resistant protective layer formed by thermally welding high-density virgin polypropylene sheets to the interior surfaces of structural substrates. This creates a continuous, waterproof, and gas-tight barrier that safeguards steel, concrete, and plastic vessels or tanks from aggressive chemicals such as strong acids, alkalis, solvents, and industrial effluents.

Designed for both new construction and refurbishment projects, PP Lining combines mechanical toughness with chemical inertness, ensuring long-term integrity and low maintenance.

Detailed Features and Advantages

Wide Chemical Compatibility

Resistant to aggressive chemicals such as hydrochloric acid, sulfuric acid, caustic soda, phenol, ketones, and alcohols without blistering or cracking.

Seamless, Welded Installation

Precision thermal welding eliminates joints and leak points, ensuring superior leak-proof performance and safety.

Thermal and Mechanical Stability

Maintains strength from -20°C to +100°C with excellent impact resistance and flexibility to withstand service stresses.

Food-Grade and Hygienic

Smooth, non-porous surfaces prevent microbial growth and contamination, ideal for pharmaceutical and food processing applications.

Custom Thickness & Color Options

PP linings available from 2 mm to 10 mm thickness with multiple color options to meet process and identification needs.

Ease of Maintenance & Cost Efficiency

Smooth surfaces simplify cleaning and offer longer service life than rubber or epoxy coatings, reducing lifecycle costs.

Applications

- Chemical storage vessels for acids and alkalis

- Pickling plants and battery rooms with acid containment pits

- Effluent Treatment Plants (ETP) – channels, sumps, and tanks

- Pharmaceutical and food processing equipment

- Industrial floors, bunds, and spill containment areas

Installation & Quality Assurance

Reconsky’s trained installation teams carry out rigorous surface preparation including grit blasting or chemical cleaning to ensure optimal adhesion and weld integrity. Our process includes:

- Thermally welded seams verified through non-destructive testing

- Leak testing under hydrostatic pressure conditions

- Strict adherence to material certification and installation standards

- Comprehensive documentation and client approval at every stage

Why Choose Reconsky PP Lining?

With over a decade of expertise in high-performance composite linings, Reconsky delivers project-tailored solutions using certified virgin polypropylene materials. Our offerings include fast delivery, professional installation, complete after-sales support, and competitive pricing for outstanding long-term value.

Frequently asked questions

PP lining is a corrosion-resistant barrier created by thermally welding virgin polypropylene sheets to the inner surface of tanks, pits, floors, and equipment to protect the base material from aggressive chemicals. It is especially suitable where excellent resistance to a broad range of acids, alkalis, and solvents is required, but extreme mechanical loads or very high temperatures are not present. Compared to rubber or epoxy coatings, PP lining provides a seamless thermoplastic surface with superior chemical resistance and no risk of brittle cracking or debonding in normal service. Versus FRP lining, PP lining is preferred where a purely thermoplastic, food-grade, or easily weldable solution is desired and the substrate already provides structural strength, such as MS or RCC tanks. For chemical, ETP, and battery room applications in Gujarat, PP lining offers an excellent balance of performance, cost, and ease of repair.

Reconsky PP lining is widely used in chemical processing plants, electroplating units, battery rooms, and effluent treatment plants where aggressive acids and alkalis are handled daily. Typical applications include lining of MS or RCC chemical storage tanks, reaction vessels, neutralisation pits, drain trenches, sumps, and secondary containment bunds. In ETPs across industrial clusters such as Ankleshwar, Vapi, and Dahej, PP lining protects RCC basins and channels from acidic or alkaline effluents. Pharmaceutical and food-processing facilities also benefit from smooth, non-porous PP linings that provide hygienic, easy-to-clean surfaces and minimise contamination. Industrial floors in high-spillage zones use PP lining for durable, chemically resistant, and washable protection.

Reconsky typically provides PP lining in sheet thicknesses ranging from about 2 mm to 10 mm, selected based on chemical severity, mechanical load, and service conditions. Standard PP linings perform reliably across a temperature range of approximately -20 °C to +100 °C, covering most ambient and moderately hot process applications. Sheets are thermally welded on-site to create fully sealed, leak-proof joints, with weld integrity verified through spark testing or other inspection methods. Colour options can be customised for process identification or hygiene requirements, offering flexibility to meet operational and regulatory needs.

Installation begins with thorough surface preparation of the substrate, including cleaning, de-rusting, and profiling to ensure proper support and anchoring. PP sheets are then mechanically fixed or anchored as required and thermally welded using specialised hot-air or extrusion welding equipment operated by trained technicians. Critical areas such as seams, corners, nozzles, and penetrations are detailed carefully to avoid stress concentrations and leak paths. After installation, welds are checked using spark testing and visual or non-destructive inspection methods, and hydraulic testing may be performed where applicable. Reconsky also provides documentation and test records to support quality audits and regulatory inspections.

PP lining isolates aggressive chemicals from steel and concrete substrates, preventing corrosion, spalling, and leakage that would otherwise shorten asset life. This protection reduces shutdowns for civil repairs or tank replacement, improving plant availability and operational reliability. The smooth, non-porous surface enhances safety and cleanliness by making spills easier to clean and reducing the risk of chemical penetration or contamination. Over the long term, lower maintenance requirements and reduced repair frequency translate into strong return on investment compared to bare RCC or MS structures with basic coatings. For chemical, pharmaceutical, and ETP facilities in Gujarat’s regulated industrial zones, PP lining also supports compliance by helping prevent soil and groundwater contamination.